Business View Magazine

5

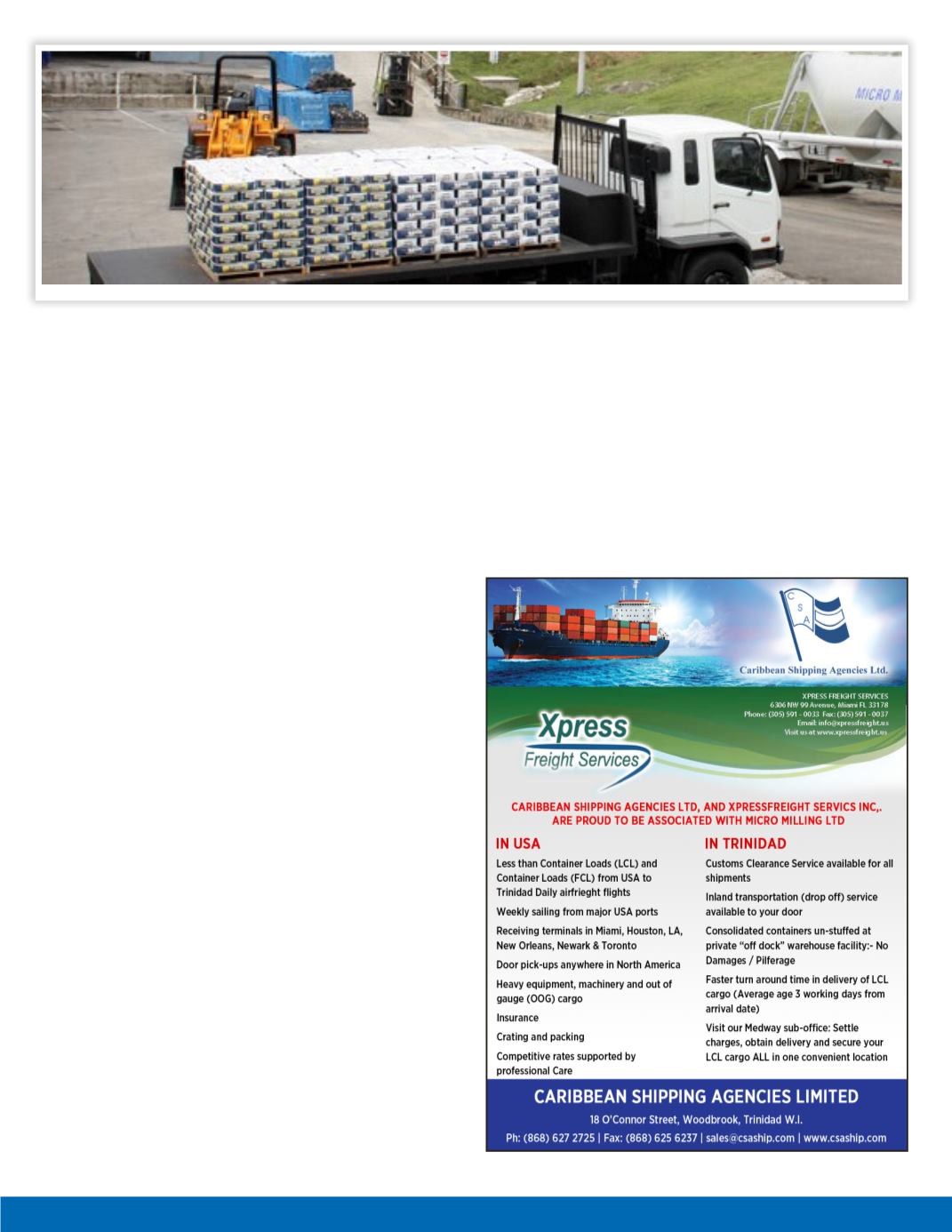

Micro Milling gets its raw sand from quarries on the

island and its cement from Trinidad Cement Ltd. Then

it does all the processing. It does not sell any of its

products direct to consumers, but rather relies on

hardware or tile stores for their distribution. They, in

turn, act as the company’s sales force.

De Verteuil explains how the company’s commitment

to servicing the users of its products plays out in its

day-to-day operations: “We have a good relationship

with the tilers as well. Trinidad is not a very large place.

We know some of the main tile contractors in the mar-

ket. We keep our ears to the ground and make sure

they are happy with our product. If they’re not happy,

say, with the way something is drying, if it’s drying too

fast, or too slow, if it’s not sticky enough, if they don’t

like the packaging – we listen to those guys who actu-

ally use the product. I think that’s very important.”

De Verteuil further clarifies what sets Micro Milling

apart from the competition: “We focus so much on

quality. We spent quite a bit of time, effort and mon-

ey setting up our own internal lab a couple of years

ago. It has all the latest equipment capable of doing

all the tests related to all the standards that our prod-

ucts meet. Usually, what companies do, is they send

their products to the [United] States – there’s a place

called the Tile Council and they test for ANSI (American

National Standards Institute) standards. This process

could take up to three months before results are re-

ceived . . . but we do all our own testing. We do send it

to the States to be verified that our tests are correct,

but that is a large part of ensuring quality for us.”

In its ongoing quest for that high level of quality, Mi-

cro Milling hosted a training workshop, last year, at the

Royal Hotel in San Fernando, Trinidad, conducted by

the National Tile Contractors Association, Inc. (NTCA),