82 November 2015 - Business View Caribbean

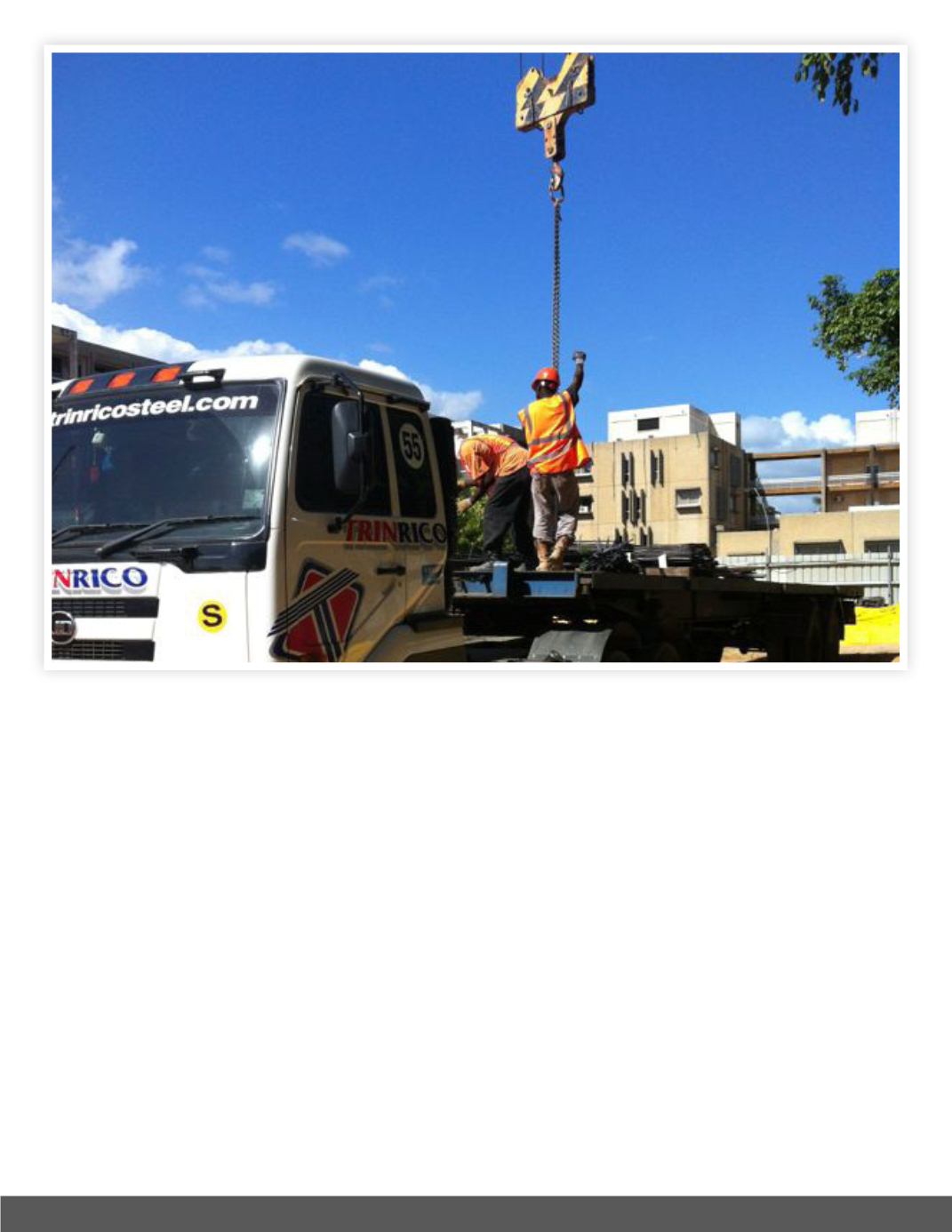

gone a lot further downstream with them. For exam-

ple, in the beginning, my father was manufacturing

chain link fencing, chain link fence fabric, nails, weld-

ing wire mesh, and re-bar from coil. Those are still our

core products, today. But in each and every one of

those products, we’ve added value and more range.

For example, we used to purchase re-bar in coils and

only straightened them to standard length to sell them

as re-bar in bundles; but now, we are processing re-bar

from both coil and bar and we are distributing both

coil and bar, nationwide and regionally. Clients are

submitting their bar-bending schedules based on their

construction drawings and we are delivering all of the

material cut and bent into stirrups and shaped bars.

And in addition, we’ve also started assembly; clients

submit engineer drawings of what they are going to

do with the pieces they would be assembling into col-

umns, or piles, or complicated mats, and we do the as-

sembly in our facility and deliver them ready to install.”

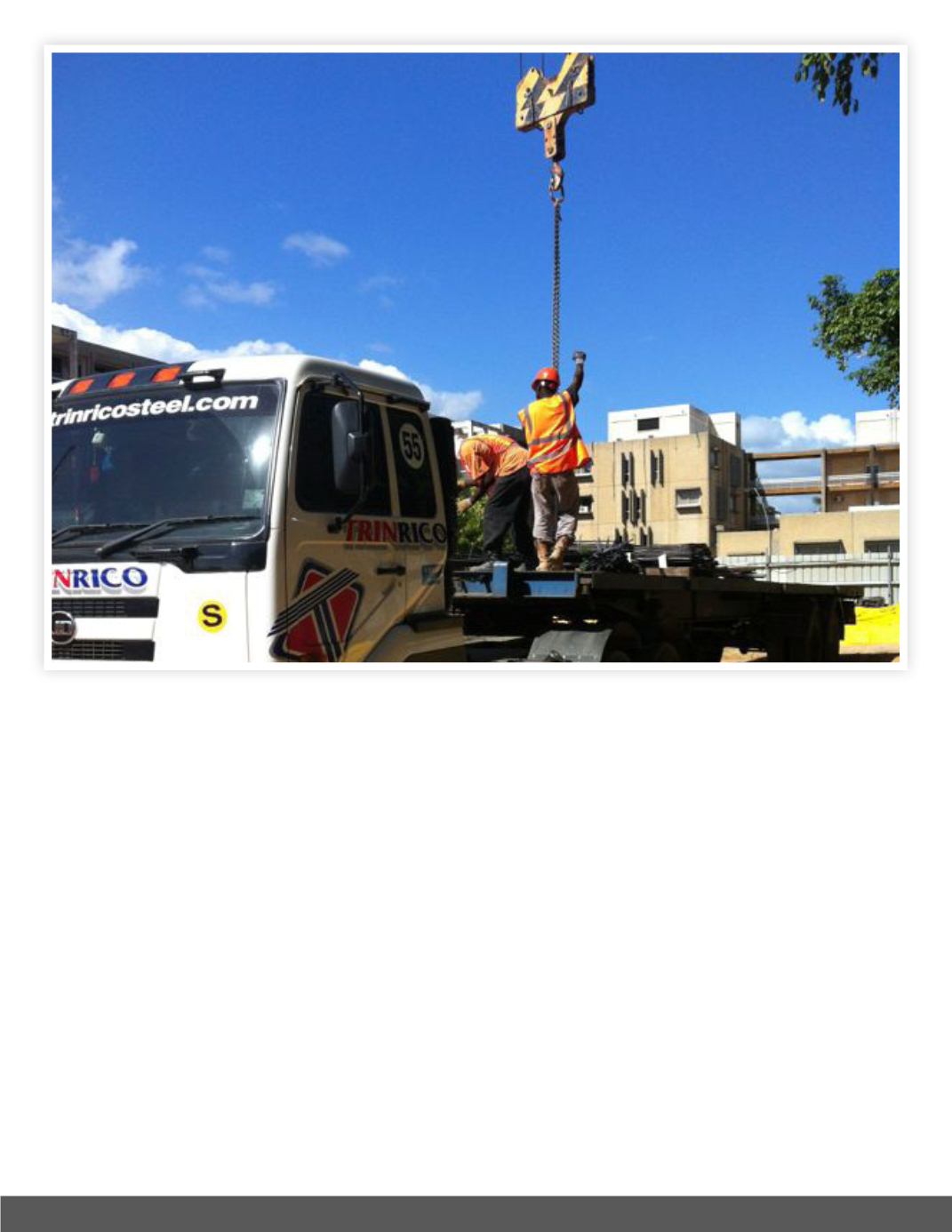

Ramoutarsingh stresses that Trinrico is known for the

quality of its materials. “Not only are we very proud

of our products, but we are not sure when we manu-

facture a roll of welded mesh, for example, or a ton

of steel, if it’s going into a simple home project or if

it’s going to end up in a government project. So, all of

our products are backed up by a mill test certificate

which is traceable to the raw material and complies

with the specification. Unfortunately, a lot of our com-

petitors don’t follow this code and use rejected raw

material that’s very old, or very rusted, or undersized.

So, our largest challenge is that we are expected to