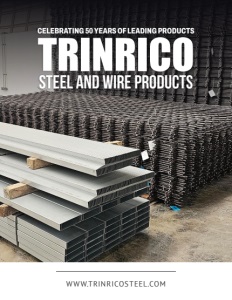

Celebrating 50 Years of Leading Products

A Family Manufacturer Rewiring Caribbean Steel Supply

From legacy machines to a new welded wire mesh plant, roll forming lines, and self-offloading logistics—Trinrico Steel and Wire Products is doubling down on quality, speed, and availability across CARICOM.

“First and foremost, we’re a family-owned business—that gives us continuity of vision,” says Daniel Ramoutarsingh, Chairman of Trinrico Steel & Wire Products.

Ramoutarsingh highlights Trinrico’s ethos: make world-class products for the Caribbean, serve hardware stores, contractors and all private sector and government projects alike while keeping quality non-negotiable.

December 2024 marked a milestone—Trinrico turned 50 and expanded. “We couldn’t meet emerging demand with legacy equipment,” Ramoutarsingh says.

The new backbone: a modern mesh plant

Trinrico replaced three aging mesh lines with a modern, purpose-built facility—new building, new machinery, new processes. The goal wasn’t just more tonnage. The Caribbean is a chain of many small markets with different standards. Some islands specify rolls, others sheets, and diameters vary by jurisdiction and application (including a wave of concrete road designs now requiring mesh reinforcement).

The new plant was engineered for rapid changeovers and short turnarounds across SKUs. Just as critical: supplier alignment.

More than mesh: a wider modernization

The mesh plant is the anchor, but it’s not the only upgrade. Over the last two to three years Trinrico has:

- Modernized chain-link fencing production with new machinery.

- Invested in roll-forming—bringing C and Z purlins back in-house at high specification.

- Expanded cut-and-bend rebar capacity (Phase Two): delivering shop-drawn, site-ready shapes and structures so contractors pay only for kilograms delivered, not scrap.

“Trinidad was quiet; the wider CARICOM boomed. We grew regionally through the lull—and we’re preparing for Trinidad’s return so we can supply both at the volumes the market expects.”

Quality you can buy anywhere—literally

Trinrico’s quality philosophy is as practical as it is ambitious: hold the highest standard and make it available everywhere. Trinidad alone has ~500 hardware stores; contractors building a road in a rural district should be able to walk into any outlet, ask if the mesh came from Trinrico, and use it immediately on government-class work.

That ubiquity is costly—it demands consistent chemistry and QA, tight distribution, and logistics that don’t fail—but it democratizes opportunity. “We’re empowering all of our clients to meet specification,” Ramoutarsingh says. “Everyone can participate in major projects.”

Logistics as a value proposition

The capital program extended to the yard and the road. Trinrico added an upgraded fleet of specialized forklifts, overhead cranes, upgraded trailers, and most customer focused – self offloading trucks with cranes.

“We could not do what we do now without those upgrades,” Ramoutarsingh says. “Clients want speed and efficiency without disruption; the trucks with cranes allow their site equipment to keep working on their needs, while we are able to discharge materials on sites and ports independent to the availability of their site equipment or lack thereof.”

The global steel whiplash—and how Trinrico navigated it

Ramoutarsingh points out that the pandemic was one shock; geopolitics was another. Tariffs, freight swings, and wars rewired steel flows in areas including:

- Ukraine produced a large percentage of the World’s steel plates and related items pre war.

- Russia was a major exporter of billet—even backstopping Turkey when it ran short.

- Israel is a substantial importer of Turkish rebar.

Operations and culture: change by design

Ramoutarsingh notes that Trinrico used the last three to four years to re-engineer how the plant works, highlighting:

“I had a strong sense that the old ways were not sustainable,” Ramoutarsingh says. “Competition sharpened, costs surged, and clients needed more speed and certainty. Our people—long-standing and new—stepped up.”

Why timing mattered

An engineer on the mesh project told Ramoutarsingh mid-pandemic: When markets come back, you’ll be ready. He was right. As ministries and developers across CARICOM began specifying concrete roads with mesh reinforcement—and as regional projects accelerated—Trinrico’s new line and aligned wire-rod supply hit stride at the same moment.

“When timing meets preparation, you serve the region when it needs you most,” Ramoutarsingh says.

Collaboration that compounds

Trinrico’s operating model is relationship-driven end-to-end characterized by:

- New investments by Trinrico and it’s critical raw material suppliers aligned perfectly.

- Ports & haulers: affiliated contractors who “stepped up” with Trinrico to match the tempo.

- Hardware & contractors: a distribution network positioned to deliver spec-compliant products across islands without friction.

“The relationships have become more personal-more mutual trust,” Ramoutarsingh says. “We make decisions together and considerations for each other’s respective roles and companies you don’t typically make in this business.”

The next 18–24 months: finish, add, scale

It is very clear when outlining his objectives and the direction his company will be moving, emphasizing working towards:

- Finish Phase One: button up the mesh plant—it’s running to plan; now it’s about refinement.

- Add barbed wire capacity: commission the second line to meet regional growth.

- Launch roll- forming; introduce C and Z purlins this month-returning a capability many clients have been requesting. However Trinrico has resolved to raise the standard of compliance in terms of yield and tensile strength and coating protection to one that better serves the construction needs throughout the region. The highest reinforcement properties with the maximum anti corrosion coating and therefore most resilient against the typical cause of failures.

- Execute Phase Two: expand cut-and-bend rebar to a new layout and throughput that can serve Trinidad’s rebound and CARICOM’s pace simultaneously.

“We’ve grown in CARICOM while Trinidad was down,” Ramoutarsingh says. “We’re getting ready for Trinidad’s return.”

Sidebar: Trinrico’s Quality-Availability Flywheel

- One standard, everywhere: Manufacture to the highest spec and make it buyable at any hardware—so every contractor can meet government-class requirements.

- Aligned upstream: Wire-rod supply timed to mesh commissioning for chemistry consistency and volume certainty.

- Self-offloading fleet: Trucks with cranes reduce site congestion, port dwell, and schedule loss.

- Cut-and-bend, roll-forming: Deliver site-ready steel and structural purlins to compress critical path.

- People & process: Dispatch, maintenance, and operator training redesigned for speed + reliability.

AT A GLANCE

Who: Trinrico Steel and Wire Products

What: A leading and trusted manufacturer, distributor and exporter of steel & wire products that is expanding to accommodate anticipated regional growth in the construction sector.

Website: www.trinricosteel.com

PREFERRED VENDORS/PARTNERS

Kee-Chanona Limited : www.kee-chanona.com

Kee Chanona stands at the forefront of civil engineering and construction in the Caribbean, backed by over 36 years of trusted experience. We deliver exceptional infrastructure and building solutions defined by precision, safety, and excellence—consistently meeting the highest standards of quality, performance, and professionalism.