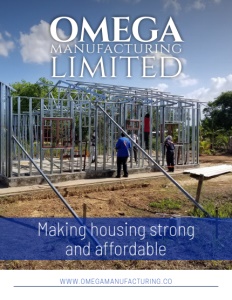

Omega Manufacturing Limited

Making housing strong and affordable

Business View Caribbean interviews Mark Agostini, Managing Director of Omega Manufacturing, for our focus on Best Practices in Construction

Omega Manufacturing Limited was established in 2014 with the noble purpose of manufacturing cost-efficient and timely housing systems. After many years in the construction and manufacturing sector and an increase in demand for affordable housing, the Agostini family saw a perfect opportunity and did not hesitate to get started. Over the years, they have been diligently developing and improving their products by making them stronger and more economical. Finally, after numerous trials and accumulation of decades of technical and engineering knowledge, Omega Manufacturing has achieved this with great success.

One of Omega Manufacturing’s top products is the The Omega Steel-Framed System. This system is comprised of cold-rolled galvanized steel sections engineered to create roofing frames, and wall panels capable of withstanding earthquakes and hurricanes. The walls of these structures are a combination of fiber cement board cladding, attached to the metal frame on either side with a hollow/insulated core. Thus far, Omega has undertaken many projects to date, ranging from low-middle income homes, office buildings, town house developments, and commercial institutional buildings. As part of the development process, they have also formulated a Hi-performance Cement Board “PolyROCK” which features increased flexural strength, along with excellent moisture resistance. PolyROCK contains no asbestos or biodegradable materials – thus making the panel long lasting, strong, and impact resistant.

Mark Agostini, Managing Director of Omega Manufacturing, shares, “We are a family-run business at Omega. At one point, we were doing construction as well as manufacturing, but for various reasons we decided to go with manufacturing only, as it was beneficial to us already having the operation set up.” He explains that over the years they have experimented using different systems and imported various types of board products. As a result, they eventually settled on using a steel-framed and cement board system, and set up a plant in Trinidad, to start manufacturing and selling.

At the company’s in-house lab, testing is done every single day. Especially during COVID lockdowns, they were doing heavy research and development about various ways to innovate and become more competitive on the market. Omega tried a variety of different additives when developing PolyROCK, as they needed to create a product based on a majority of materials available in Trinidad – which may be different than what manufacturers in the U.S. have, versus manufacturers in Central America or China.

Agostini explains, “They all vary a little bit and we’re trying to compete with those factories. COVID definitely hampered our progress, but we are on a steady path to achieve what we set out to do. The majority of our raw materials for the PolyROCK cement board manufacturing process are locally sourced, but we do have to import some from China, Brazil, and the United States. However, it depends on the delivery time, availability and pricing, especially now with COVID.” With the majority of the materials being local, PolyROCK qualifies for CARICOM duty free concessions, which is a big selling point for Omega.

When it comes to customers for PolyROCK cement boards, 100 percent of the local distribution is done by Kelvin Ghany Enterprises (a large hardware store in Trinidad and Tobago). Omega is currently the only cement board manufacturer in the Caribbean. As a result they increased exports in 2021 across the region and currently supply products to Suriname, Grenada, Barbados, Dominica, St. Lucia and Antigua. They are slowly gaining market share in Guyana, as they continue to look for potential partners to work alongside.

It was a natural evolution, from manufacturing different types of housing systems, to doing steel framed housing, and then on to manufacturing the PolyROCK cement boards. The Omega team is also now working on a cement panel system, which essentially uses cold-formed steel and cellular concrete filled lightweight cement panels. This system, though still in development, will be even faster to construct. Although these may be lightweight systems, they are extremely strong and able to withstand severe weather, as a result of outstanding engineering. Agostini notes, “We have supplied some houses in Dominica that are rated for up to category five hurricanes. These houses were designed slightly different to those houses we built in Trinidad, however, once engineered accordingly, a category five rating can be achieved using a steel framed system.”

Omega Manufacturing has about 30 full-time and part-time employees, including engineers –a relatively small team but big on talent. The company had to close twice for numerous months during the pandemic, and in that time they did their best to continue paying the staff, even though they were shut down. As Agostini acknowledges, “Because good people are hard to find.”

In terms of facilities, they have two warehouses and a head office. One warehouse is totally dedicated to manufacturing the PolyROCK cement board, with the machinery and the drying rooms located there. All the equipment and the raw materials are stored in that building. The other building is for manufacturing steel and doing fabricating work; roll forming and assembling. A couple of other small products are done on that side as well, such as aluminum light frames for ceilings. Omega also recently started producing joint compounds to go with PolyROCK cement board for jointing and finishing, as well as tape for the joints.

“It’s very rewarding for our team to do the research and come up with those solutions,” says Agostini. “Along with PolyROCK cement board and the steel framed housing, we have some really low cost systems that we’re working on, because the price of housing here in Trinidad and Tobago is out of reach for a majority of the population. So we’re trying to work on the low cost systems so that people have a place to live – an alternative to using blocks and something a little bit more affordable. So it is rewarding in that sense.” He adds, “The average person could come to us, tell us what they want, and we could design a steel framed house for them. We also work with developers, Habitat for Humanity, and have done some projects for the government.”

Over the next three to five years, Omega Manufacturing has many goals they’d like to achieve, including an expanded product line, and to enter in to a few more Caribbean markets. “We want to become more of a well-known name in the Industry and have product brands that people will automatically associate with us,” says Agostini. “We’d like to be more established, to grow in-house, and to develop our other products that are not directly related to PolyROCK cement board. Hopefully, we could start doing that in 2022. Ultimately, we have plans to grow over the years. Currently, we outsource one or two items, but to expand, we would need to bring in more people to get to that level, as we increase capacity.”

While prices of raw materials will likely never go back to where they were, Agostini suggests they will probably go down a bit and eventually not be as volatile. He notes, “The price of steel, for example, is changing every week. We have some good suppliers of materials, although it takes a long time for them to reach Trinidad, depending on where we order from. COVID has really affected everything around the world, but we’re carrying on as best we can.”

Key to the business development plan going forward is that the affordable housing component of the business needs to grow significantly. As Agostini admits, “The main challenge is that Caribbean people are accustomed to doing things a certain way, so to change them to something else is indeed difficult. Although, we have seen in the past five years, a lot more people turning towards using cement board to build houses with, and the popularity of the product is growing. When using steel framed and alternative methods of construction, (other than traditional brick and concrete) once finished correctly, the completed house looks just as nice, with no noticeable difference.”

He adds, “We are a small company that is building ourself on innovation. We believe we are just as successful as large companies all over the world in terms of developing top quality products. That’s something we’re proud of. Every day we’re testing to improve our offerings.”

AT A GLANCE

Omega Manufacturing Limited

What: Manufacturer of Cement Board & cost-efficient housing systems

Where: Headquarters in Arima, Trinidad & Tobago

Website: www.omegamanufacturing.co

Email: info@omegamanufacturing.co

This information will never be shared to third parties

This information will never be shared to third parties